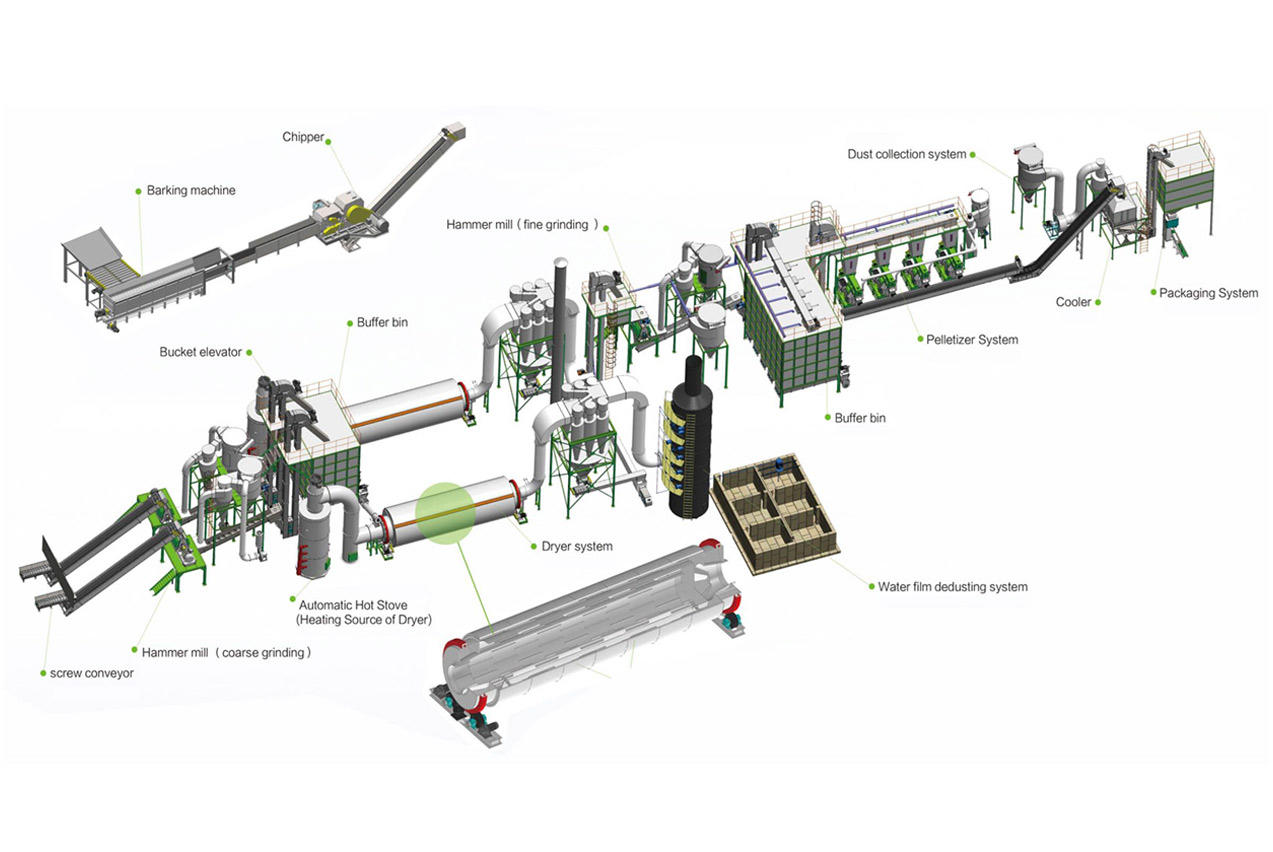

In the vast landscape of industrial machinery, the Hammer Crusher Machine stands out as an essential piece of equipment for material processing. This robust and versatile machine is integral to the efficient breakdown of various materials, from biomass to minerals. The Hammer Crusher Machine, often complemented by a Crusher Conveyor, is designed to handle high volumes of material with minimal downtime, ensuring a smooth and continuous operation.

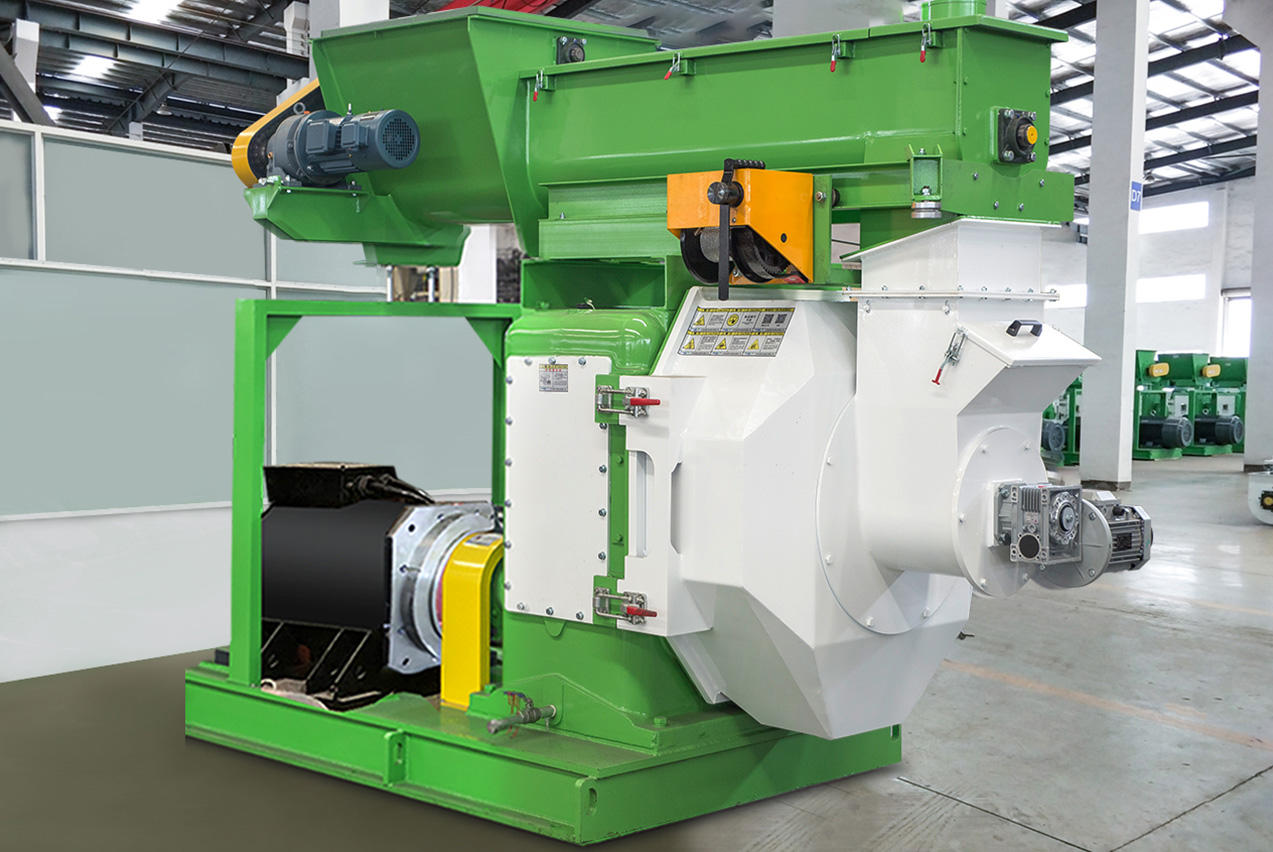

Hammer Mill Crusher: Precision and Performance

The Hammer Mill Crusher is a specialized version of the Hammer Crusher Machine, tailored for the specific needs of material reduction in industries such as agriculture, mining, And construction. with its high-speed rotating hammers, the hammer mill crusher effectively reduces bulk materials into finer particles, suitable for further processing or direct use. The Hammer Mill Crusher's design allows for a high reduction ratio, making it a preferred choice for industries requiring a consistent end product.

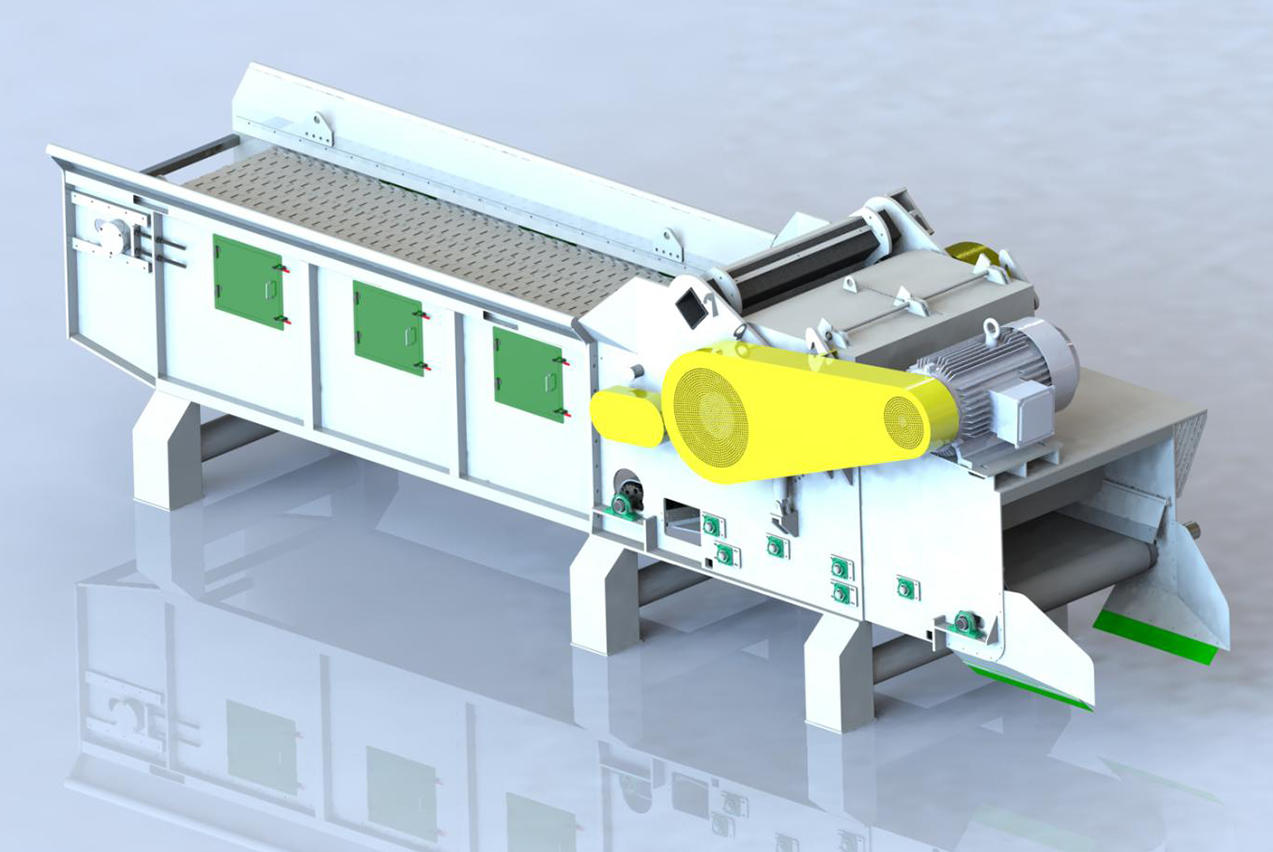

Crusher Conveyor: Streamlining Material Handling

The integration of a Crusher Conveyor with the Hammer Crusher Machine is a strategic move that enhances the overall efficiency of the operation. The Cr usher Conveyor seamlessly transports materials from the primary crusher to subsequent stages of processing, reducing manual handling and potential for material loss. This belt conveyor system is designed to withstand the rigors of continuous operation, ensuring reliability and durability in even the harshest of environments.

Belt Conveyor: The Backbone of Material Transportation

The Belt Conveyor is a critical component in the material handling process, working in tandem with both the Hammer Crusher Machine and the Crusher Conveyor. Known for its ability to handle a wide range of materials, the Belt Conveyor is customizable to fit the specific requirements of each operation. Its modular design allows for easy integration with existing sys tems, providing a flexible solution for material transportation.

Manufacturer's Strength and Commitment to Quality

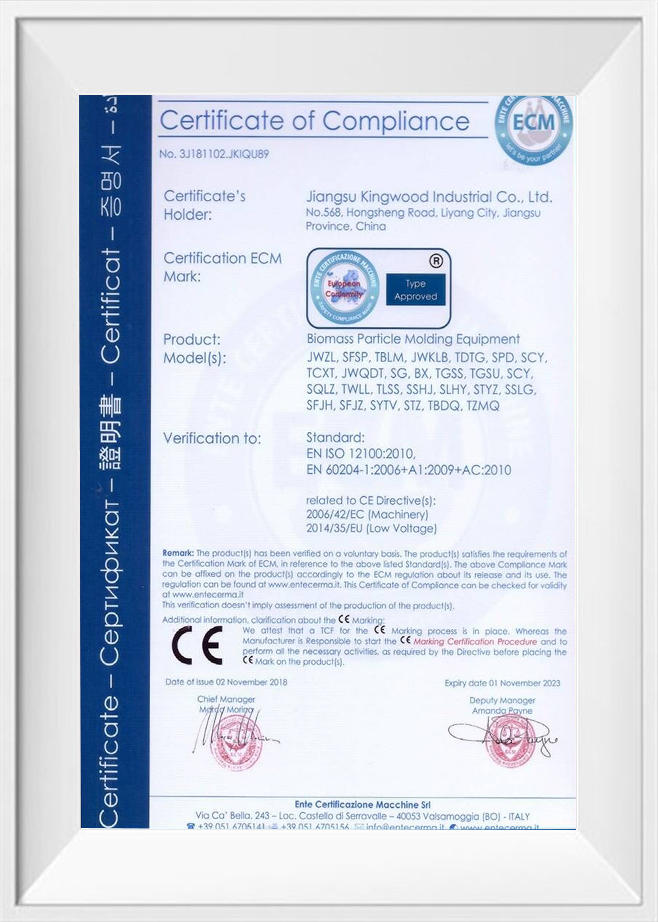

The manufacturer of these advanced machines has a proven track record of delivering high-quality, reliable equipment to clients across various industries. With a focus on innovation and customer satisfaction, the manufacturer invests in research and development to ensure that their Hammer Crusher Machine, Hammer Mill Crusher, Crusher Conveyor, and Belt Conveyor are at the forefront of technological advancements.

Product Features and Benefits

1. Durability: Constructed with high-grade materials, the Hammer Crusher Machine and its components are designed to withstand the test of time, reducing the need for frequent replacements and repairs.

2. Efficiency: The Hammer Mill Crusher's high-speed operation ensures that materials are processed quickly, improving output and minimizing energy consumption.

3. Customization: The Crusher Conveyor and Belt Conveyor can be tailored to suit the specific dimensions and capacities required by the client, ensuring a great fit for each unique operation.

4. Safety: With safety at the forefront of design, these machines feature multiple safety mechanisms to protect operators and ensure a secure working environment.

5. Low Maintenance: The Hammer Crusher Machine and associated equipment are engineered for minimal downtime, reducing the need for extensive maintenance and upkeep.

6. Environmental Considerations: The manufacturer is committed to producing machinery that adheres to environmental standards, minimizing the ecological footprint of their operations.

7. Innovation: Continuously improving and updating their product line, the manufacturer ensures that the Hammer Crusher Machine and related equipment incorporate the latest technological advancements.

8. Cost-Effectiveness: Offering a competitive price without compromising on quality, the manufacturer's products provide a cost-effective solution for businesses looking to invest in reliable machinery.

The Hammer Crusher Machine, along with the Crusher Conveyor and Belt Conveyor, forms a powerful trio in the material processing industry. The Hammer Mill Crusher's precision and the seamless integration of conveyor systems ensure that material processing is not only efficient but also cost-effective.

English

English

日本語

日本語

한국어

한국어