Biomass Machinery Parts Manufacturers

Biomass Machinery Parts Manufacturers

Depending on the machine, there are different classifications of parts. Biomass Pellet Mill Parts include Ring Die, Lubricating Grease, Roller, Shaft, Safety Pin, Hoop, Gear; Biomass Hammer Mill Parts include Blade, Screen, Lubricating Grease; Biomass Chipper/ Crusher Parts include Screen, Blade.

Specialized machines make Kingwood's Roller Shells. The press rolls produced have the characteristics of high dimensional accuracy of the inner surface, low roughness of the mating surface, less runout of the outer circle to the inner-circle axis, and high cylindricity of the out-surface. Its stability in use is high, and its life expectancy has reached the leading level in China.

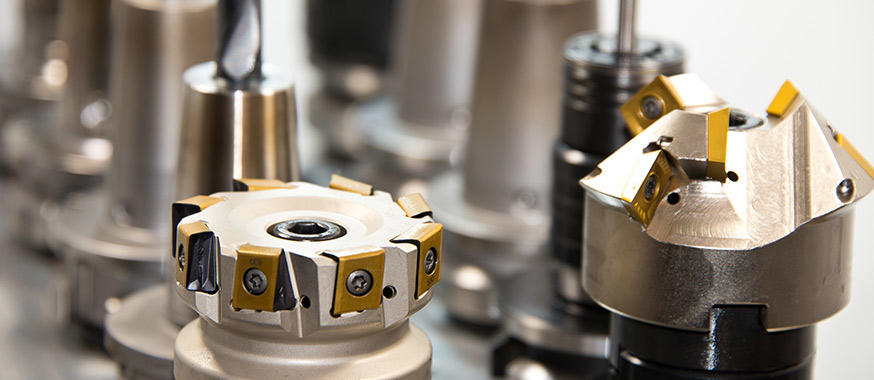

Pellet Mill Parts are the core components of any pellet mill machine. They are designed to withstand the rigors of high-pressure environments, where biomass materials are compacted into uniform pellets. The durability of these parts is paramount, as they are subjected to constant wear and tear. Manufacturers invest heavily in research and development to create Pellet Mill Parts that are not only robust but also precise in their operation.

The Pellet Machine Parts are the driving force behind the pellet production line. These components work in harmony to ensure that the biomass materials are processed efficiently and effectively. From the feed hopper to the die and roller, each Pellet Machine Part plays a critical role in the overall performance of the machine. The quality of these parts directly impacts the output and consistency of the pellets produced.

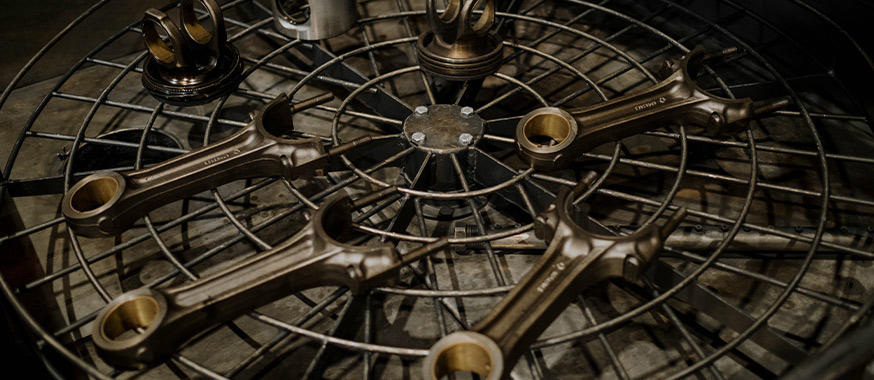

Industrial Machine Parts are designed to meet the demands of large-scale production facilities. These parts are built to handle heavy loads and operate under challenging conditions. The robustness of Industrial Machine Parts is essential for maintaining the high output required in industrial settings. Manufacturers prioritize the strength and longevity of these parts to minimize downtime and ensure a continuous production process.

The Biomass Machinery Parts are the foundation of the pellet production industry. They are responsible for the transformation of raw biomass materials into valuable pellets used for energy production. The quality, durability, and precision of these parts are crucial for the success of any pellet mill operation. Manufacturers must continuously innovate and improve the design and materials used in the production of Biomass Machinery Parts to meet the ever-evolving demands of the industry.

Regular maintenance and timely replacement of Biomass Machinery Parts are essential for the longevity and efficiency of the pellet mill. Worn-out or damaged parts can cause decreased production output and poor pellet quality. It is crucial for operators to monitor the condition of their Pellet Mill Parts, Pellet Machine Parts, and Industrial Machine Parts and replace them as needed.

Investing in high-quality Biomass Machinery Parts is a wise decision for any pellet mill operator. Quality parts not only ensure the smooth operation of the pellet mill but also contribute to the overall efficiency and profitability of the operation. By choosing reliable and durable parts, operators can minimize downtime and reduce the frequency of replacements.

Pellet Machine Parts are the heart of the pellet-making process. These include key elements like bearings, gears, and motors that drive the machinery. The quality of Pellet Machine Parts directly impacts the output and efficiency of the pellet production line. Manufacturers invest in robust materials and advanced manufacturing techniques to produce parts that are reliable and long-lasting.

Industrial Machine Parts are built to handle the demands of heavy-duty applications. In the context of biomass machinery, these parts must be capable of withstanding high pressures and temperatures. The design of Industrial Machine Parts focuses on both strength and flexibility to adapt to various industrial environments and applications, ensuring the machinery's resilience and longevity.

Biomass Machinery Parts encompass all the components necessary for the efficient operation of pellet mills and related machinery. These parts are not only limited to the core machinery but also include auxiliary systems that support the overall functionality of the production line. The comprehensive nature of Biomass Machinery Parts allows for a seamless integration into existing systems, providing a complete solution for biomass processing needs.