2024.04.10

Industry news

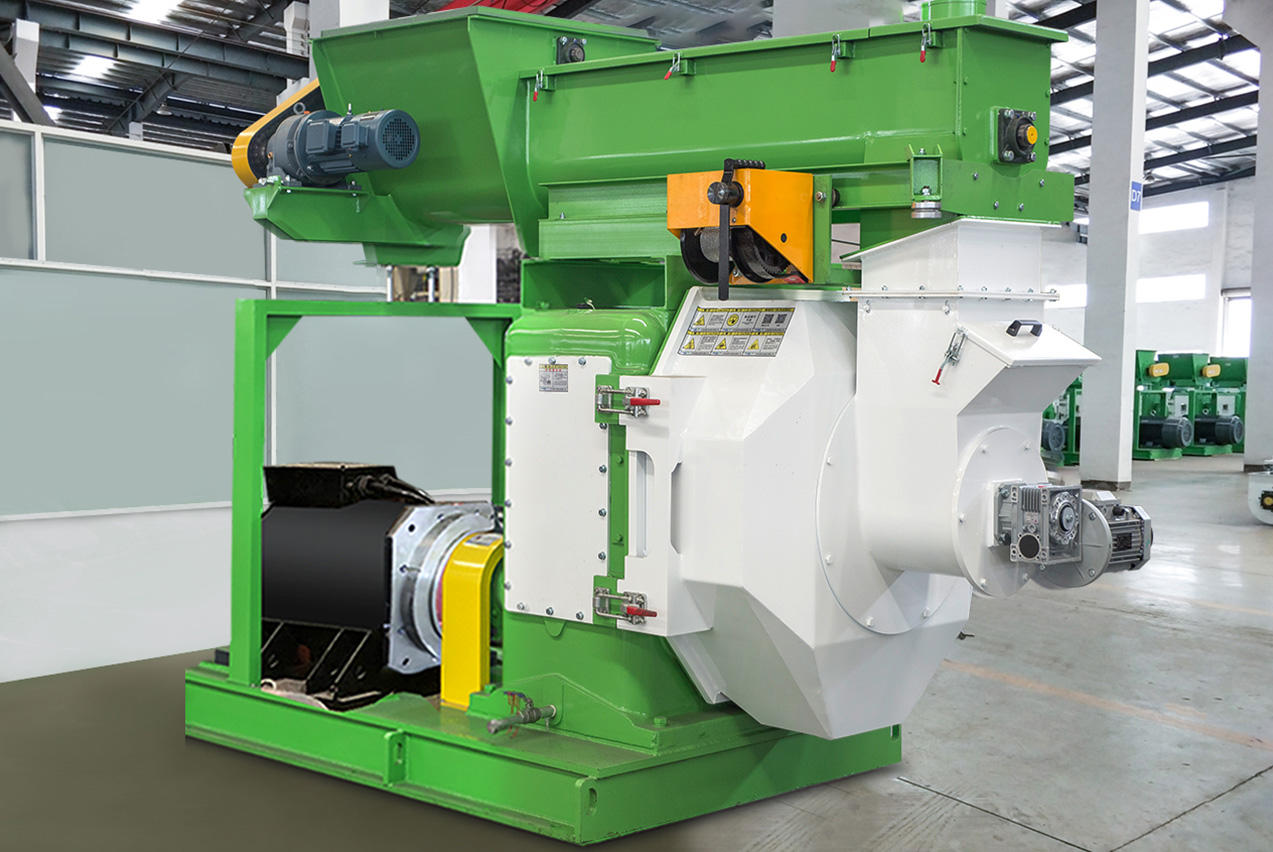

Compared with traditional energy production methods such as coal and fuel oil, is the operation of a biomass pellet machine more environmentally friendly?

2024.04.03

Industry news

Is the energy consumption during the operation of the biomass hammer machine related to the speed and quality of biomass processing?

2024.03.29

Industry news

How does the rice husk pellet machine compare to other types of pellet machines in terms of energy efficiency and sustainability?

2024.03.25

Industry news

How does the rice husk pellet machine contribute to the overall sustainability of rice production and waste utilization?

2024.03.20

Industry news

How does the integration of renewable energy sources (e.g., solar, wind) into industrial wood pellet production facilities affect their energy efficiency and sustainability?

English

English

日本語

日本語

한국어

한국어